You can find here the presentation of different projects (private, associative or academic).

These overlays are published here as an informative support. By consulting them, you agree to use them only for personal purpose.

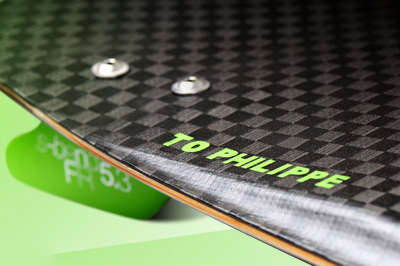

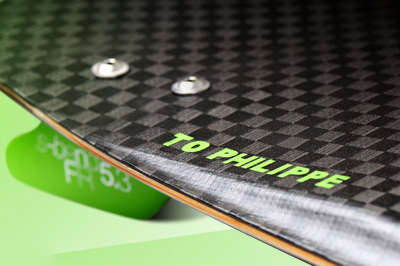

June 2012 - Kiteboard demonstrator

Credit photo :

Esther Bussy

I have taken kiteboarding as a substitution to mountain riding sports for about a year now. With the experience acquired I felt that it was time to investigate the kiteboard technology.

Here is my kiteboard demonstrator. It is dedicated to my uncle Philippe which recently passed away and inspired me greatly regarding my professional orientation and handcraft passion.

The range for this design is freeride, the technical specifications are:

Size: 136*40 cm

Weight : 2,250kg

Concave bottom

Angled fins

Differential torsional/longitudinal stiffness

Deflective tips

Wooden edge

June 2010 - SBC#1 : Carbon fiber longboard

Sept 2007 to Jan 2010 - Design and manufacture of a highly economical (low fuel consumption) vehicle

Spring 2009 - Magnet Pack : Innovative ski/snowboard carrier - Relation product/market/customer and industrial design

Spring 2009 - Mr Compost : Herb garden in the style of A Di Alessi

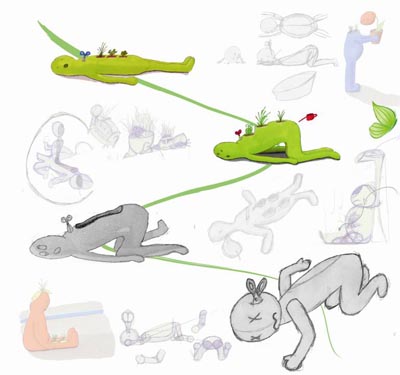

Spring 2009 - Glideride : Camcorder stabilizer - Value analysis and creativity methods

This project was a group assignment. The purpose was to design a camcorder stabilizer by using value analysis and creativity methods (FAST, TRIZ...).

Here is a video of the CAD representation.

Spring 2009 - Eco reverse engineering of a flashlight

This project was a group assignment. The goal was to analyze an existing product and decrease its environmental impact. We managed to bring the Eco-indicator from 216 to 91 millipoints (Eco-indicators 99), by modifying the source of energy, the source of lightning or the materials for example.

Spring 2007 - Design and manufacture of a downhill skateboard wheel (longskate)

I managed to design and manufacture a prototype of a downhill skateboard wheel within 6 weeks. It was my bachelor individual degree project in Polymer engineering at

Napier University (Edinburgh).

Here you can download a test video of the wheels.

First semester 2006 - Design and manufacture of a streetluge

A friend and me designed and manufactured two streetluges made of composite/aluminium structure with composite fairing. We did it during our spare time.

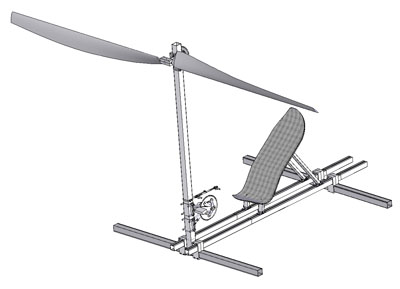

First semester 2006 - Design and manufacture of a propulsion system for an aquatic Human Powered Vehicle

First semester 2004 - Design and manufacture of a steadycam

This is a mechanical system which permits to stabilize a camcorder. This team project was done as a part of my baccalaureate (equivalent to A level).

Here you can download a ski video which was made with it; no effects were had during the editing.